Wooden Panels

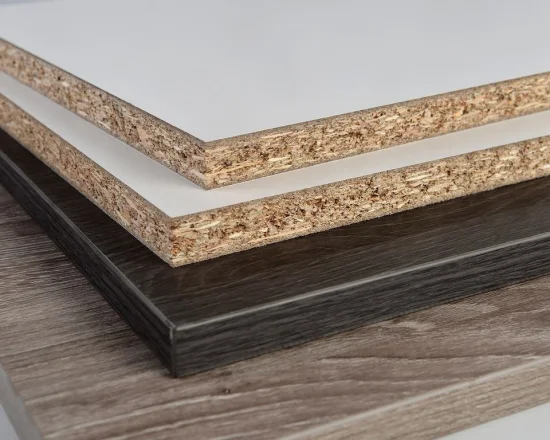

Melamine boards are a type of laminate made from melamine resin, a durable plastic material. They can be applied to particleboard, plywood, or MDF to create a low-pressure laminate (LPL) with various colours, patterns, and textures. Melamine boards are used for kitchen and bathroom cabinetry, shelving, display counters, office furniture, and more. Melamine boards are a budget-friendly option without sacrificing quality and durability. They are also easy to clean and resistant to scratches, stains, and water. However, melamine boards have some disadvantages, such as the possibility of warping if water penetrates the substrate, or chipping if not installed properly. Melamine boards also require edge banding to cover the unfinished edges

MDF board, composed of wood fibers, covered with an impregnated decorative paper with melamine resin

Cladding & Ceiling MDF has a very smooth surface devoid of knots and kinks. It is a good alternative to natural wood without compromising on its appearance

(MELAMINE FACED CHIPBOARD OR PARTICLE BOARD)

Chipboard is composed of wood particles (core of the brown board}, covered with a decorative paper impregnated with melamine resin

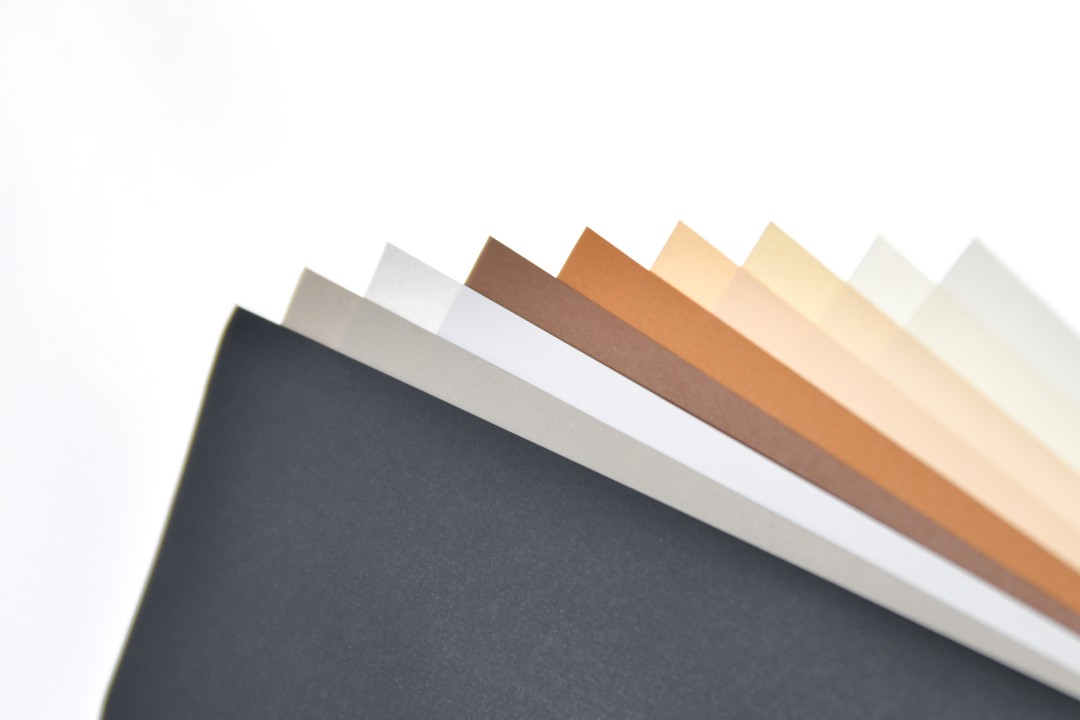

(IMPREGNATED DECOR PAPER)

Decorative paper is also known as Melamine paper. It can be used as solid colours or printed designs (ex. wood grains, fantasy, marble .. .). Usually, it is pressed on boards surface using special synthetic resins, by hot press machines.

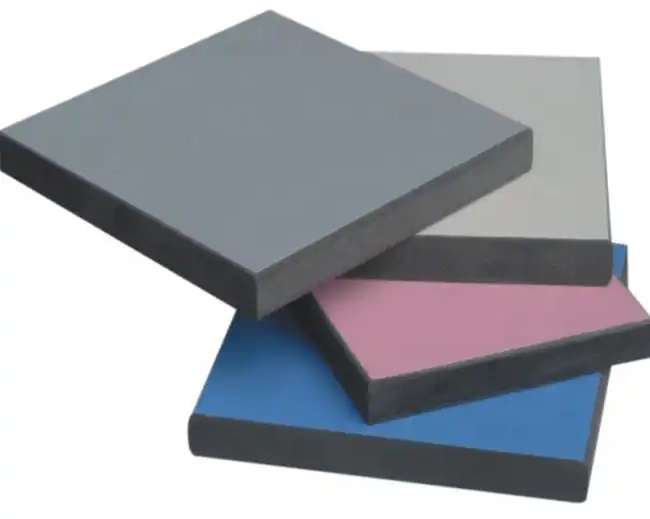

Compacts and HPL boards are types of laminates that are made by pressing layers of paper and resin under high pressure and heat. They are used for various applications such as furniture, countertops, wall panels, and partitions. Compacts are thicker than HPL boards and have a through-dyed core, while HPL boards have a thin decorative surface layer

(COMPACT DENSITY IBREBOARD)

High-density Kraft fiber board, mass dyed in black, core of the board in black, white, brown or sandwich (fiber}, covered with two layers of barrier paper (brown or white) and a decorative paper impregnated with melamine or phenolic resin, on each side, resulting in a multilayer composition.

iCOMPACT DENSITY IBREBOARD)

High-density Kraft fiber board, core of the board in brown (fiber), covered with a decorative paper impregnated with melamine and phenolic resin, on each side, resulting in a multilayer composition.

OUTDOOR (COMPACT DENSITY FIBREBOARD)

High-density resistance compact board, formed by a core of sheets of Krah paper (grey or white core) and a decorative paper on one side, all impregnated with melamine resin.

(HIGH PRESSURE LAMINATE AND POSTFORMING)

High Pressure Laminate (HPL} consists of fiber layers impregnated with thermo setting resins and subjected to a high-pressure process consisting in the simultaneous application of heat and pressure.

Resins offer a 3 types of resins, Urea-formaldehyde resin (UFJ, phenolic formaldehyde resin (PF), melamine Urea-formaldehyde resin (MUF).

(UREA-FORMALDEHYDE RESIN)

Urea-formaldehyde (UFJ resins are the most important type of adhesive resins for the production of wood based panels.

(PHENOLIC FORMALDEHYDE RESIN)

Phenolic resin (PF) is the resin synthesized from the condensation reaction of phenol with formaldehyde in the presence of a catalyst.

(MELAMINE UREA-FORMALDEHYDE RESIN)

Melamine Urea Formaldehyde Resins (MUF) are poly-condensation products of the reaction of formaldehyde with urea and melamine.

HOF HIGH DENSITY FIBREBOARD OR COMPACT BOARD)

These flooring planks are real hardwood flooring. They carry all the attributes of other engineered hardwood flooring except this type is specially made to click together during installation.

(POLYVINYL CHLORIDE EDGE BANDING)

Edge banding is a thin material used to seal the exposed and raw edges of plywood. Heat sensitive adhesive on one side is applied to the board while the other side acts as a barrier against dirt and moisture.

(RAW CHIPBOARD / PARTICLE BOARD)

Chipboard is also known as a practice board. This type of board is made by mixing wood particles with resin and with heat and pressure applied during manufacture a rigid board is created.